ABOUT GVD

GVD is Dedicated to Improving the Surface of Things.

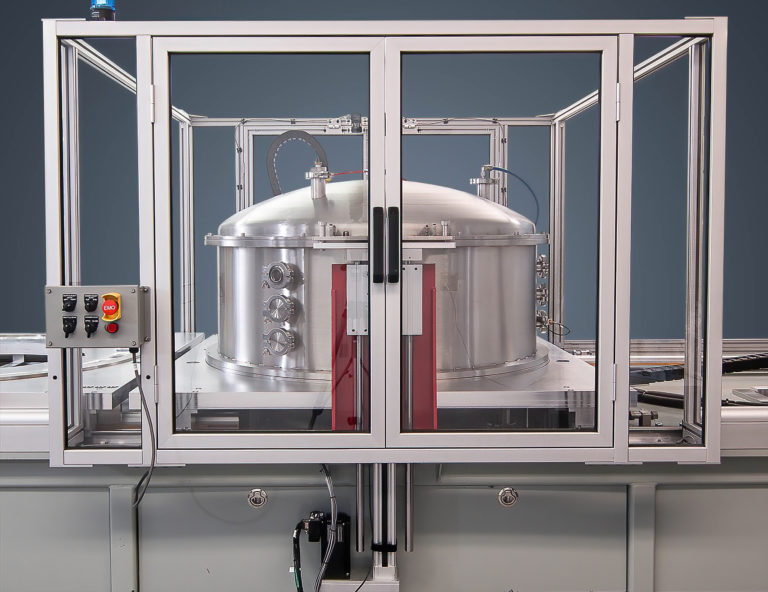

GVD’s growth has been organic, driven by a market demand for customized nano- and micro-coating solutions. GVD Corporation spun out of MIT’s Chemical Engineering laboratories in 2001 as the commercializing arm of a unique polymer vapor deposition technology. With years of experience developing coatings for a variety of market sectors from the laboratory to commercial use, GVD delivers advanced performance and sets a new standard for coating solutions. Our customers use GVD polymer coatings to secure a firm competitive advantage in their respective markets.

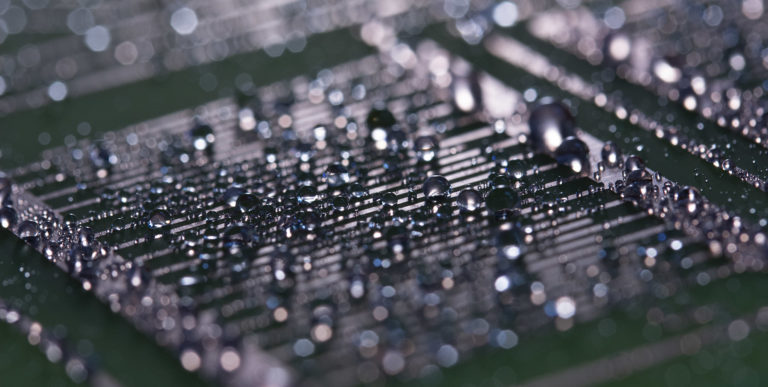

Ongoing development and access to industry experts in vapor deposition, continuously drives research and development to pinpoint innovative markets and applications, and create groundbreaking advancements in products and manufacturing. GVD currently serves a broad customer base with coating solutions for the aerospace, land and sea defense, industrial, medical and consumer industries.

We’re Leaders In Coating Innovation

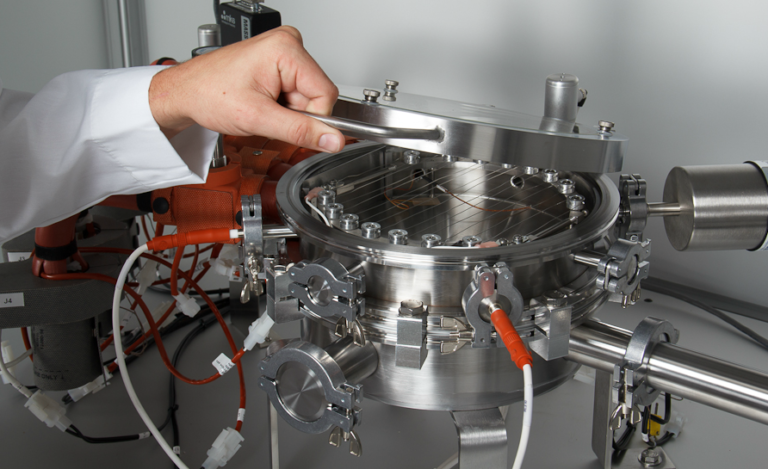

GVD scientists and engineers are continually researching and developing new coatings with novel properties that are smart, functional, and even radical. Our team is a diverse and experienced group of chemists, process engineers, and manufacturing professionals with the scientific background and the product application process expertise necessary to develop state-of-the-art multifunction coatings that improve the surface of a variety of things.

Leadership Team

Yes!

I’d like to discuss my application with a GVD engineer.