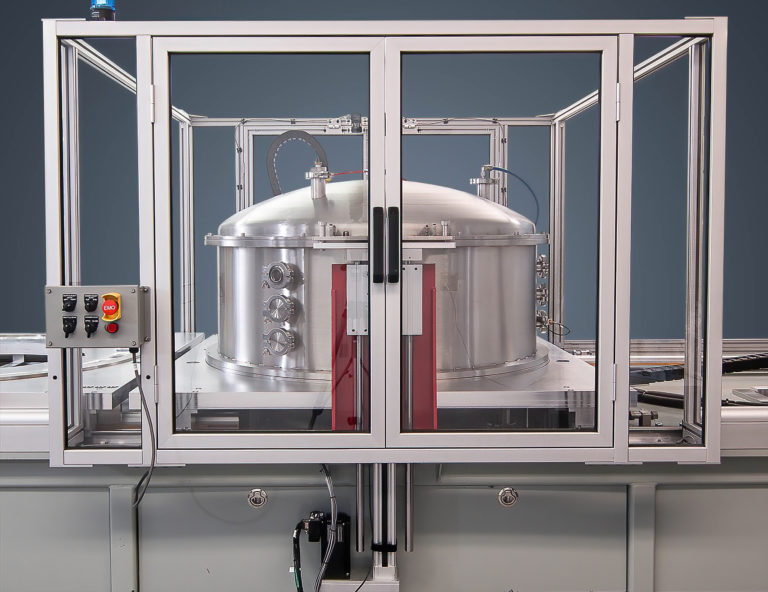

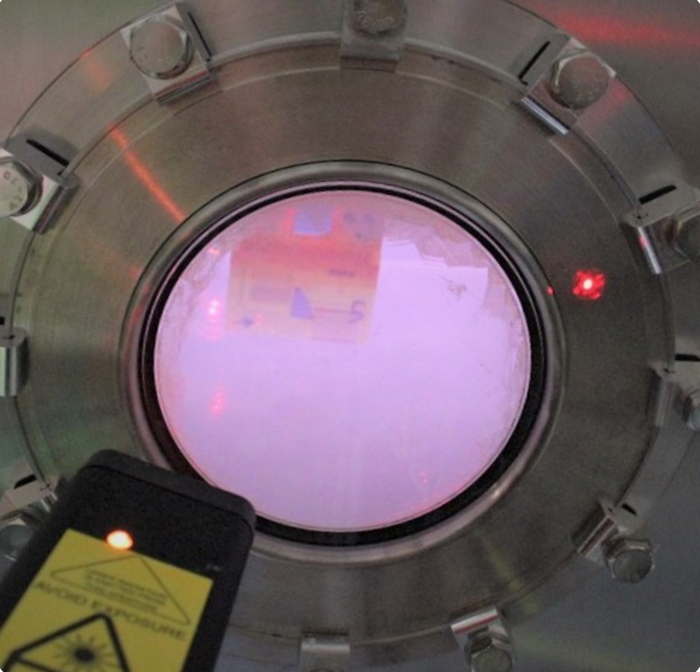

Research Equipment

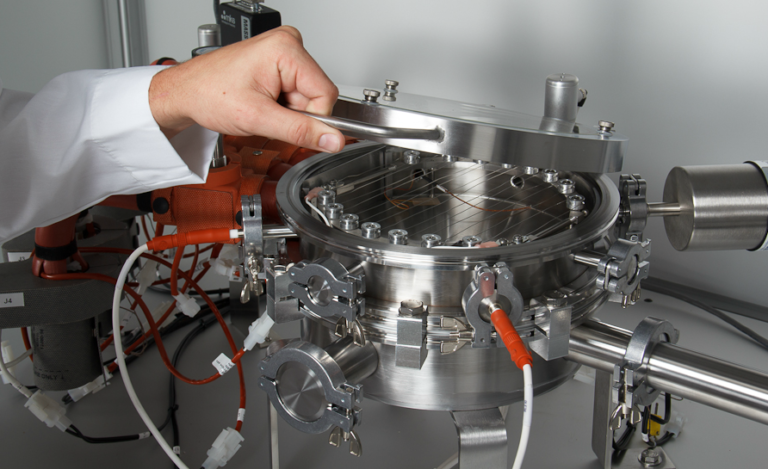

Research and development laboratories that perform and develop their own CVD materials can also benefit from GVD technology. We offer small scale, customizable R&D equipment that enables research centers to bypass the costly and time consuming process of developing a custom polymer chemical vapor deposition (CVD) system and get to experimenting right away.