- September 30, 2022

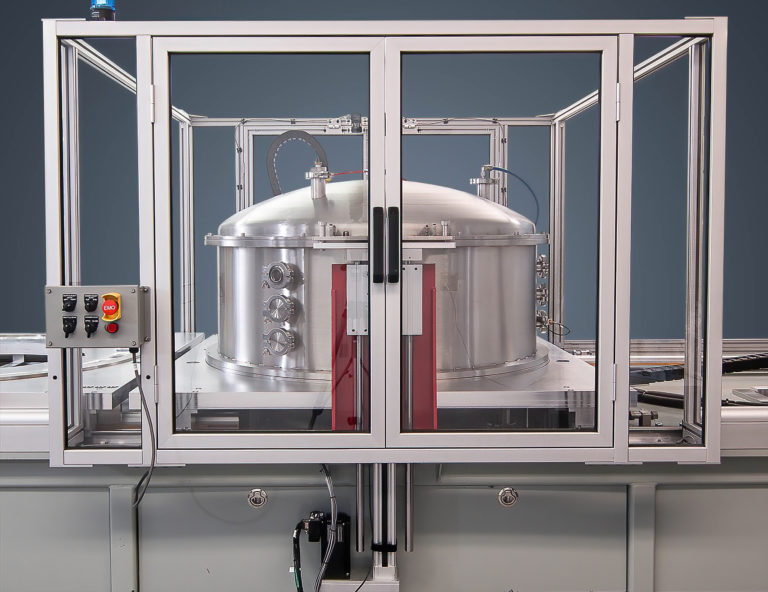

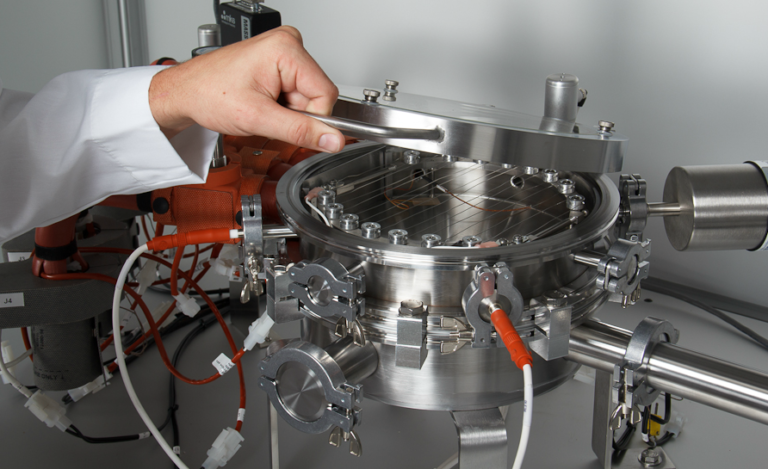

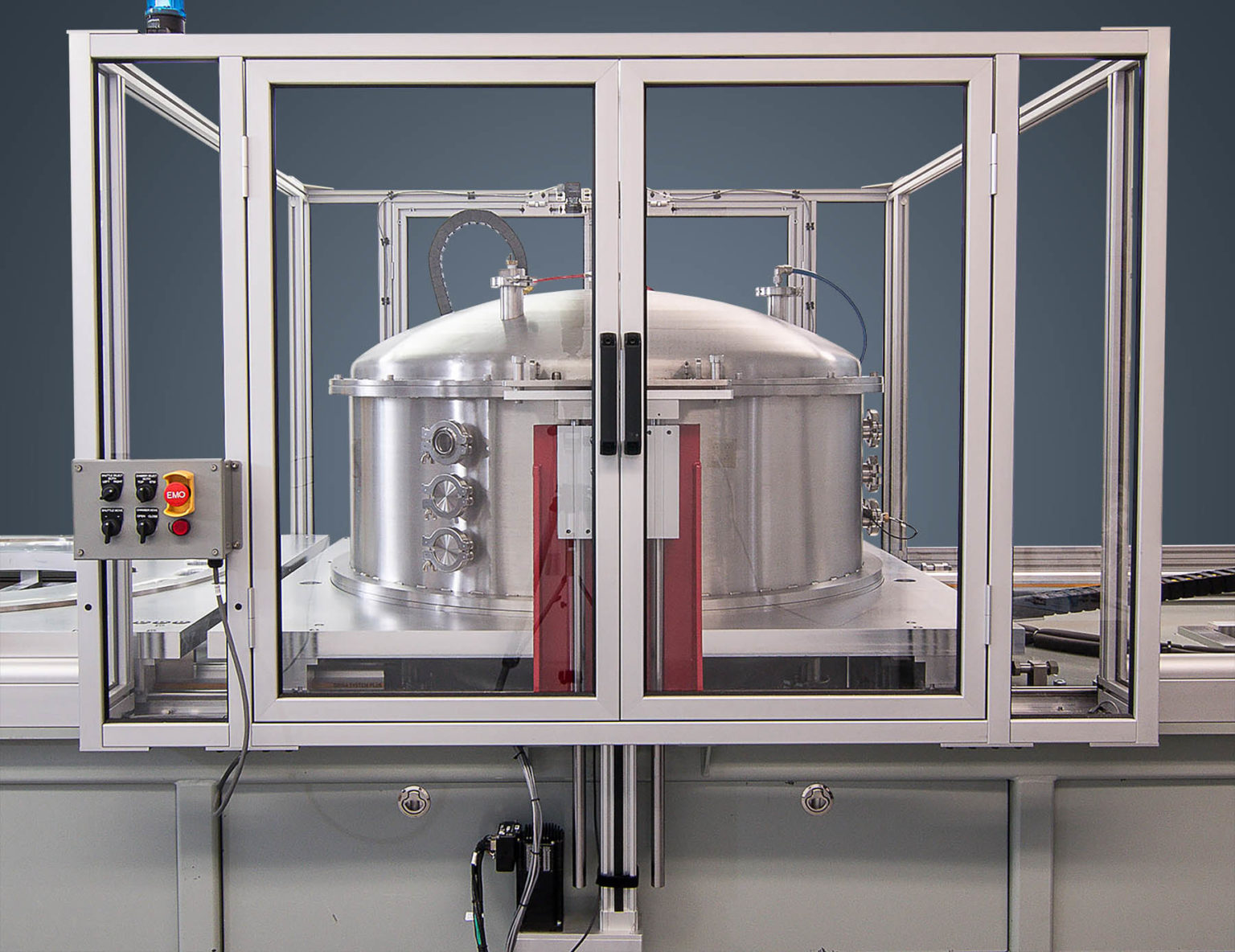

Kayaku Advanced Materials (KAM), a leading specialty materials provider bringing innovative materials to the microelectronics market, has completed the acquisition of SignalSeal from GVD Corporation. The investment in SignalSeal provides a significant compliment to KAM’s existing Paratronix® parylene conformal coatings division.