In recent years, organometal halide perovskites have become the most promising class of next generation solar materials due to their extremely high efficiencies (>20%), their amenability to cheap manufacturing and the potential for >40% efficiency when paired with other solar technologies.4–6. With their relative ease of fabrication, potential for roll-to-roll processing and extremely high efficiencies,...

Read MoreAn Ultra-thin & Optically Transparent Barrier Coating Solution

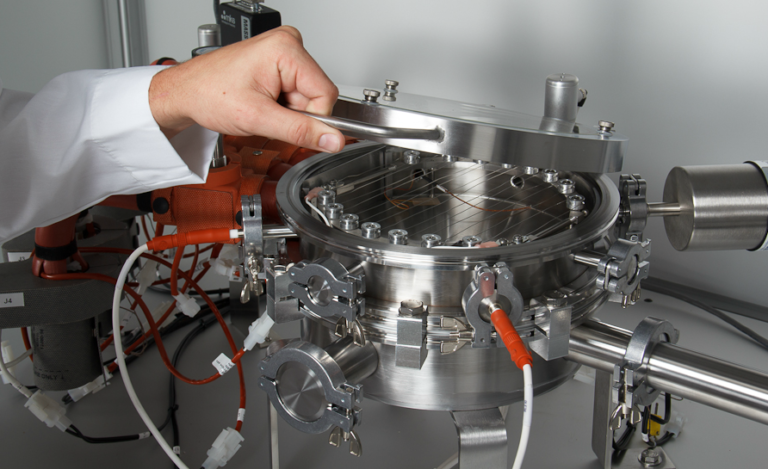

GVD’s Multilayer Barrier coating provides increased level of protection against corrosion or contamination, by serving as a universal barrier against the ingress of gases (e.g. oxygen, water vapor, hydrogen, acids) and liquids. The coating can provide similar water vapor and oxygen transport reductions as metallized films with much higher optical transparency, to a variety of flexible and rigid substrates.

- High performing gas transport barrier with no added mass and minimal added thickness (<2 microns). Superior to parylene and comparable to metallized polymer film.

- Suitable for delicate substrates and flexible substrates

- Optically transparent down to 200 nm.

- Barrier performance achieved with minimal thickness (2 microns or less) and fully conformal.

Competitive Comparison

| Coating Type Property | Water vapor transmission rate (85% humidity) | Oxygen transmission rate | UV transmission 350 nm | Conformality |

|---|---|---|---|---|

| GVD Barrier (2 microns) |

0.38 g /m2/day | 1.8cc/m2/day | 90% | |

| Parylene | 0.75 g /m2/day (Parylene C @ 25 microns) |

110 cc /m2/day (Parylene C @ 25 microns) |

50% (Parylene N/C) |

(Parylene N/C) |

| Metallized PET | 0.75 g /m2/day 0.1 g /m2/day |

0.9 cc/m2/day | <5% | Not possible |

Multilayer Barrier Coating can be Utilized in:

Flexible Electronics

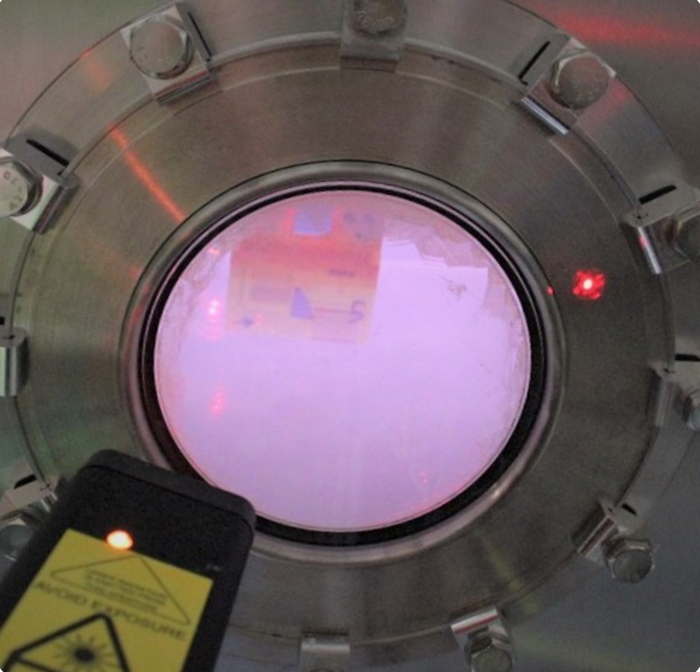

Thin-film Solar Cells

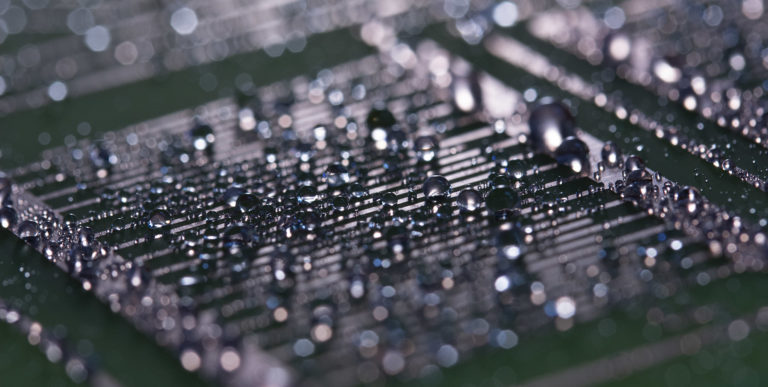

Printed Circuit Boards

Parts That Would be Damaged by Excessive Moisture

Application Spotlight

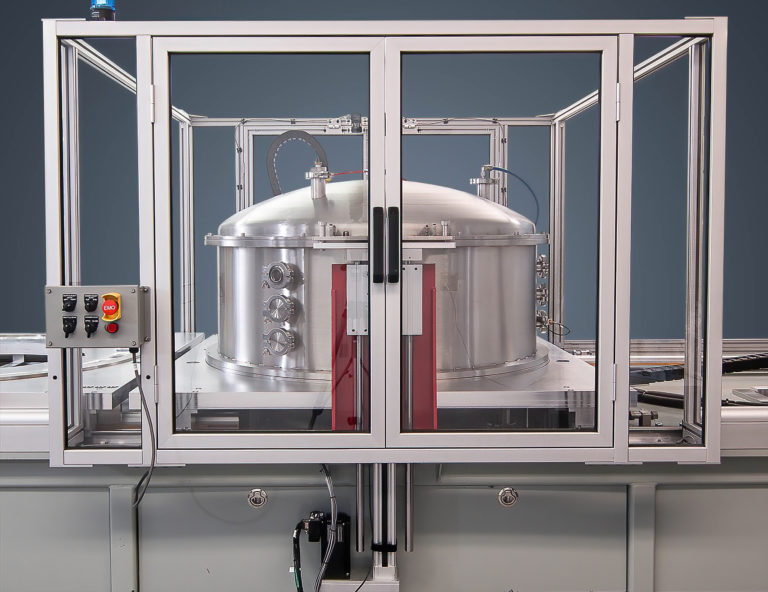

GVD Helps You Move Quickly From Evaluation to Production

When you choose GVD for your project, you’ll work directly with our coating specialists for R&D collaboration through to production-scale coating services. Our coating service is scalable to fit your requirements from the evaluation phase through to high volume manufacturing.

Evaluate

Test different coating technologies and processes on a small number of units.

Validate

Coat engineering volumes for in-depth evaluation.

Scale

GVD can quickly scale up and transfer coating operations to customer’s facility via technology licensing.

Multilayer Barrier FAQs

I’d like to discuss how Multilayer Barrier can help us provide protection against the ingress of gas & moisture