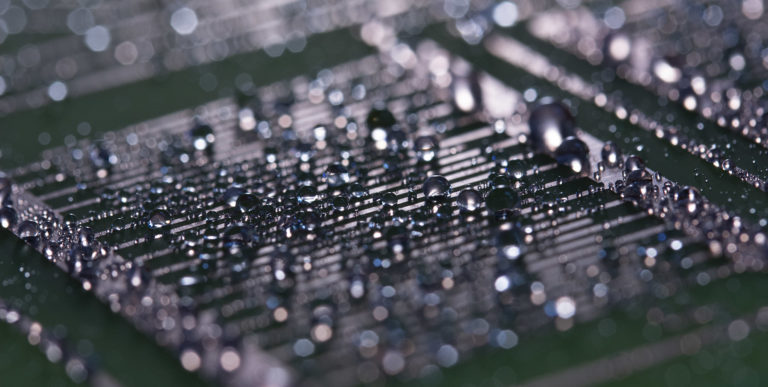

Electrowetting has emerged as one of the most commonly used techniques for manipulating the movement of small liquid droplets on surfaces, utilized in lab-on-a-chip devices, optics, and displays. It is achieved via electromechanical reduction of a liquid’s contact angle with an applied electric field on a solid surface. An electrowetting material system will typically consist...

Read MoreCoatings for Unprecedented Droplet Motion

Electrowetting has become one of the most widely used tools for manipulating tiny amounts of fluids on surfaces, achieved via electromechanical reduction of a liquid’s contact angle on an electrically-charged solid surface.

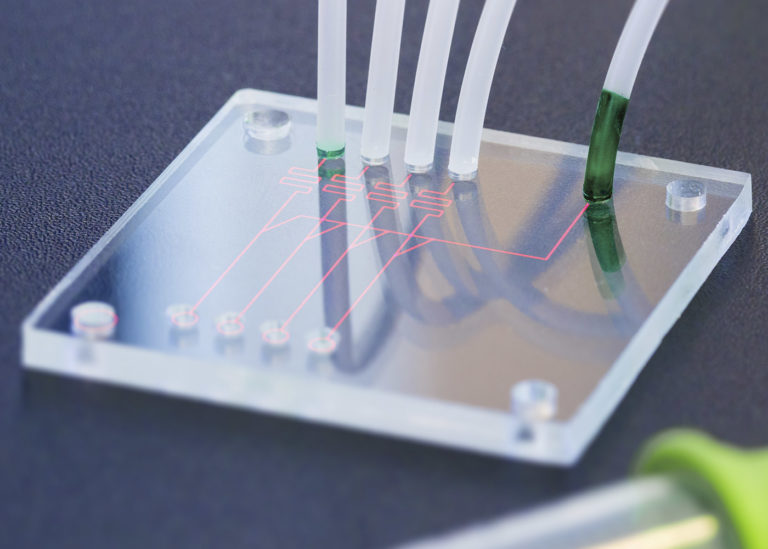

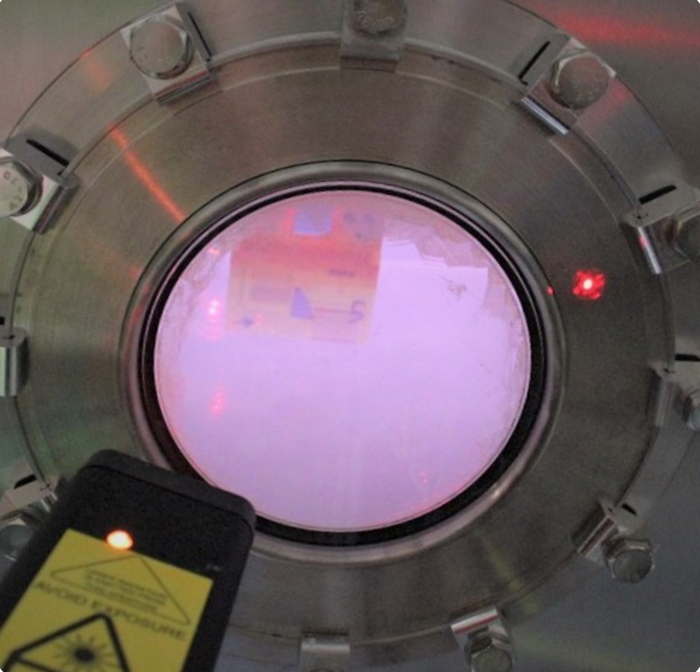

GVD has developed its own electrically and chemically stable electrowetting material system for precise control of liquid streams and droplets. A multilayer design is optimized for the modification of the wetting properties of the surface with a maximum range of response via an applied electric field, eliminating the need for pumps or valves.

Dry, surfactant-free coating application that does not require curing or annealing

Ultra-thin, uniform and pinhole-free film with maximum voltage response

Designed for long term stability, with high breakdown voltage, low defect density and UV & acid stability.

Conformally coats complex-shaped surfaces without plugging small cavities

Exhibits ultralow pinning to ensure minimum hysteresis

Optically transparent coating for analysis and feedback

Electrowetting Coating Properties

| Electrowetting Coating Properties | |

|---|---|

| Breakdown Voltage | > 100 V |

| Electrowetting Actuation Voltage (Δθ=40°, water in oil) | 9 V |

| Contact Angle Modulation (water in oil) | 70°- 170° |

| Electrowetting Contact Angle Hysteresis (water in oil) | < 2° |

| Static Contact Angle (water in oil) | 170° |

| Water Absorption | < 0.1% |

| Optical Transparency | > 95% (300mm-1200mm) |

Electrowetting Coatings can be Utilized in:

Microfluidic Devices

Lab-on-a-chip

Electrowetting Displays

Switchable Optics

MEMS

Download GVD's Comprehensive Data Sheet for Electrowetting Coatings

Application Spotlight

GVD Helps You Move Quickly From Evaluation to Production

When you choose GVD for your project, you’ll work directly with our coating specialists for R&D collaboration through to production-scale coating services. Our coating service is scalable to fit your requirements from the evaluation phase through to high volume manufacturing.

Evaluate

Test different coating technologies and processes on a small number of units.

Validate

Coat engineering volumes for in-depth evaluation.

Scale

GVD can quickly scale up and transfer coating operations to customer’s facility via technology licensing.

Electrowetting FAQs

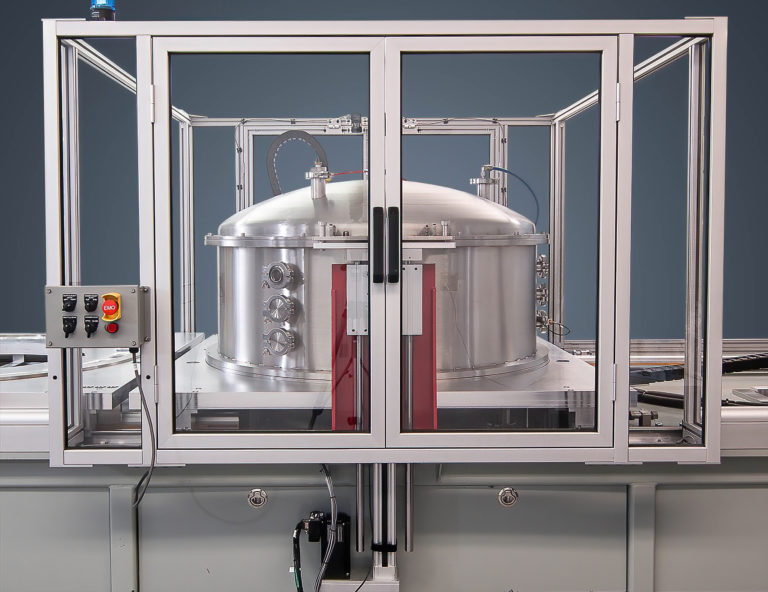

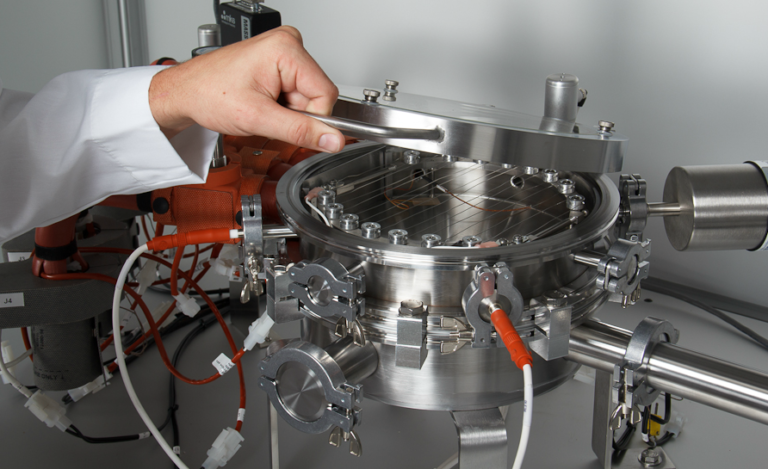

Coating is applied via a contactless, solvent-free, chemical vapor deposition process in specialized chambers. This process produces uniformly coated samples that require no curing.

The excellent properties of GVD’s coatings allow an actuation voltage of less than 10 VDC. For greater wetting modulation, voltages as high as 100 VDC may be applied.

GVD coating system replaces parylene as the dielectric layer and Cytop as the hydrophobic layer. For water in silicone oil, we were able to achieve contact angles upwards of 170° with < 2° hysteresis. GVD’s proprietary dielectric material provides superior dielectric strength and ensures low leakage currents, while the low-energy and ultra-smooth hydrophobic surface ensures the maximum wetting control with minimum applied voltage and excellent reversibility.

GVD’s coating material is resistant to water absorption, chemical breakdown, delamination and electrochemical degradation.

See All of Our Whitepapers, Journal Articles, Stats and Case studies, and client stories

Yes!

I’d like to discuss how Electrowetting Coatings can help us advance our microfluidic technology