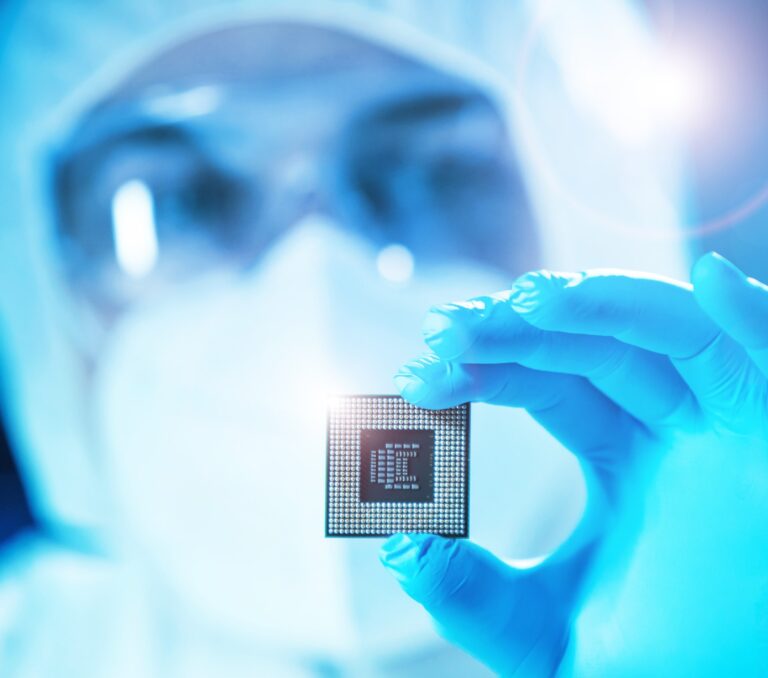

Parenteral drug administration using prefilled single-dose syringes has the potential to add ease and safety for treating a variety of diseases, including autoimmune, arthritis, diabetes, and others. Using pre-filled syringes presents the ability to reduce medical errors and enable patient-controlled self-therapy. However, the traditional method of coating single-dose syringes with silicone oil may pose additional...

Read MoreLubricious Coatings

For Transforming Surface Performance

When Reducing Friction Matters

Many medical and industrial applications require lubricious or non-stick surfaces that don’t react with the sensitive chemistries and materials contacting these surfaces. Traditional coating methods often fall short of these requirements, but not GVD’s lubricious and non-stick coating. Unlike conventional spray and liquid phase coating methods, GVD’s chemical vapor deposited material is conformal in three dimensions with excellent thickness control, requires no solvent, is chemically inert, and is well-adhered to the coated surface.

Creates a Lubricious Surface

The coating process transforms surfaces to be non-stick, low friction and hydrophobic. A variety of materials can be coated, from flexible elastomers to rigid plastics and metal.

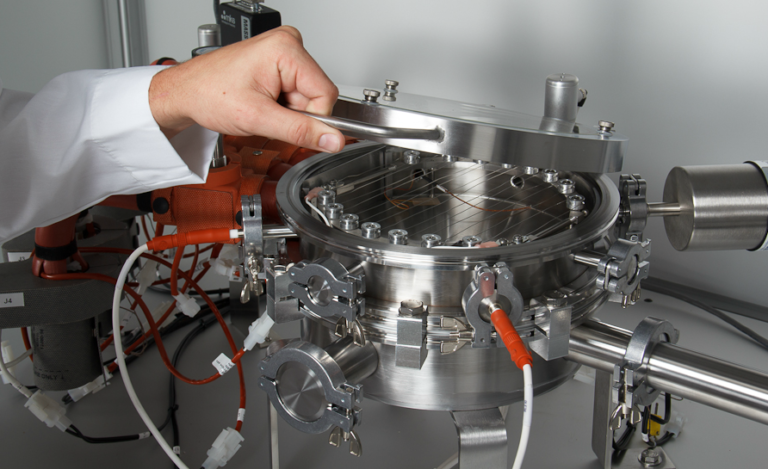

Applies Conformal & Ultra-Thin

GVD’s coatings are applied at 50 nanometers to 10 microns thick, transforming the surface with a conformal and ultra-thin membrane without pooling or degradation of surface texture.

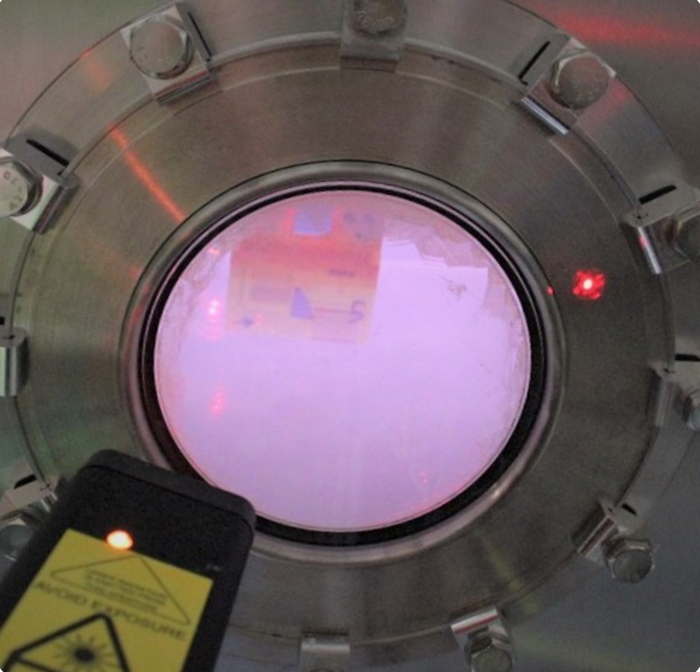

Applies Dry & at Room Temperature

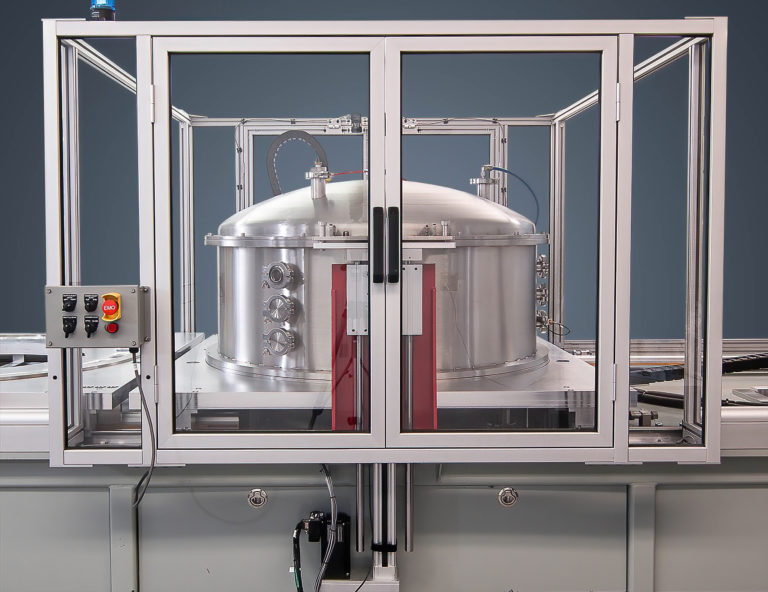

Unlike traditional spray-and-bake coatings, GVD’s material is applied through a vacuum deposition process. The coating is formed in a dry, solvent-free environment, and there is no need to expose the coating and substrate to a high temperature post-bake.

Withstands High Temperatures & Corrosive Agents

GVD’s lubricious coatings have all the benefits without the harsh processing required of some of the traditional friction-reducing coatings.

GVD's Lubricious Coatings Transform Surfaces for:

Medical Device Manufacturing

Pharmaceutical Manufacturing

Syringe Stopper Lubrication

O-Rings

Seals & Gaskets

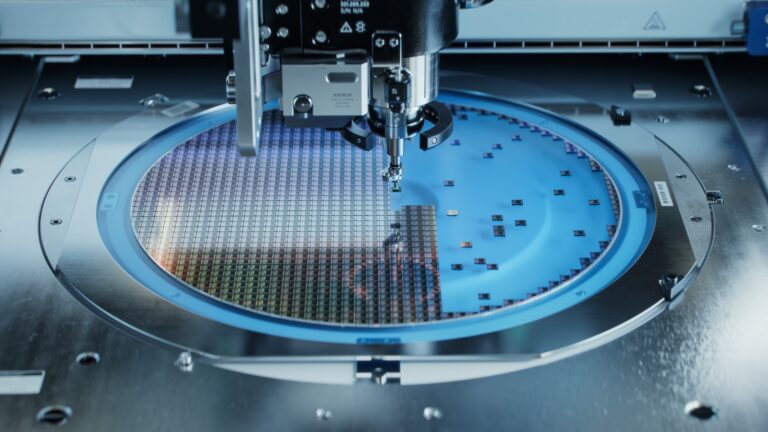

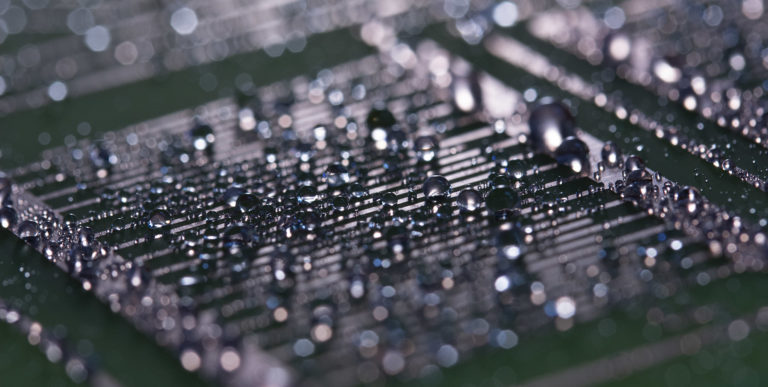

Semiconductor Final Assembly

Microelectromechanical Systems (MEMS)

Application Spotlight

Application Spotlight

Facilitating Advanced Packaging and Heterogeneous Integration

Advancements in electronics design and manufacture, as well as the general trend...

Read MoreEliminating Product Denaturing In Parenteral Syringes

Parenteral drug administration using prefilled single-dose syringes has the potential to add...

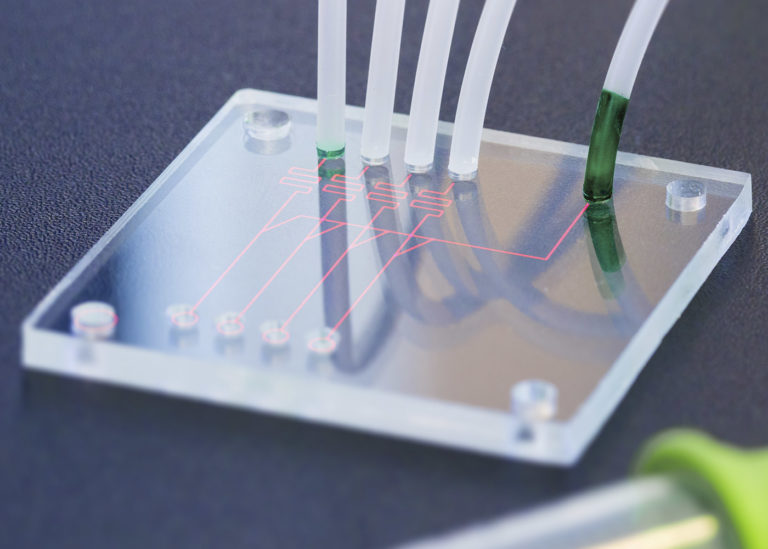

Read MoreMaximizing Droplet Motion for Microfluidics Applications

Electrowetting has emerged as one of the most commonly used techniques for...

Read MoreGVD Helps You Move Quickly From Evaluation to Production

When you choose GVD for your project, you’ll work directly with our coating specialists for R&D collaboration through to production-scale coating services. Our coating service is scalable to fit your requirements from the evaluation phase through to high volume manufacturing.

Evaluate

Test different coating technologies and processes on a small number of units.

Validate

Coat engineering volumes for in-depth evaluation.

Scale

GVD can quickly scale up and transfer coating operations to customer’s facility via technology licensing.

Lubricious Coatings FAQs

Yes! This material has been used for years to reduce friction in food and medical device industries. Contact GVD for more information on application compatibility.

Typically most applications require 50 nm to 10 microns thick of coating on a substrate. GVD will work with you to determine the ideal thickness for each application.

Yes. GVD’s coating is being used commercially for a wide variety of applications and industries, mainly as a lubricious coating for elastomers but other materials as well.

GVD typically performs small scale trials and moderate-sized application validation runs onsite. We also offer equipment sales and product licensing to help transition higher volume projects to customers’ manufacturing locations, and have extensive experience with rapid scale-ups. Contact GVD to discuss any high-running parts production requirements.

It depends on the application. GVD’s lubricious coating is a good release coating on metal substrates. It should not be used in applications that require significant mechanical abrasion, such as a sharp metal edge scraping the surface.

Most likely the answer is no. If attempting to coat inside a tube with an aspect ratio larger than 1:4, then GVD’s coating may not be best suited for the application. While the coating is conformal, it does not have good “throw” down long tubes.

It depends on the substrate and application. GVD’s coating can be IR transparent or it can have a hazy appearance at high thicknesses.

No. GVD’s coating, even though it is chemically resistant, should not be used as a chemical barrier layer.

Yes!

I’d like to discuss how GVD’s Lubricious Coatings can help us transform the performance of our surfaces.